Congratulations to our company promoted to the largest "South China Poly Real Estate" floor coatings class supplier! I warmly congratulate carborundum wearable Floor material sales first!

24-hour service hotline:4000 011 480

Tel:0750-3613461 Fax:0750-3613461-5

Email:jddp666@163.com Alibaba:https://jdtl66.1688.com/ Web:http://www.jddipi.com/

Address:18th Floor, Lile Wudong Village, Jianghai District, Jiangmen City, Guangdong Province, China (Edited by A01 Factory)

Office Address: No. 159, Lexiang East Road, Wudong Village, Lile Town, Jiangmen City

Main business: floor paint, carborundum wearable Floor, concrete sealer, and other flooring materials

Web CopyRight © 2019 Guangdong Jiangmen Jie Da Coating Material Ltd. All rights reserved. 粤ICP备11005041 Powered by www.300.cn

Links: Google MadeInChina CE Floor paint Integrated wall panels Charcoal floor Waterborne epoxy zinc-rich primer

Search Keyword:Hardened wear-resistant flooring,Epoxy floor paint coating,Sports stadium, PVC plastic,Parking Floor

样品色卡

新闻动态

生产自动化控制

自产自销一条龙

全新丰富行业经验

停车场地坪系列

墙漆涂装系列

商业地坪系列

户外地坪系列

运动球场、PVC塑胶地板

环氧树脂地坪漆涂装系列

硬化耐磨地坪系列

耐磨硬化地坪技术专栏

Epoxy Floor Technology

环氧树脂地坪技术专栏

Epoxy Floor Technology

防腐地坪运动场地坪技术专栏

Epoxy Floor Technology

荣誉证书

Certificate of honor

在线视频

video

我公司均采用进口生产自动化控制设备,能确保让您选择到最合适的地坪材料!

洁达涂料能制定准确而详细的规范要求,自产自销一条龙为每个客户带来优质的服务。

洁达涂料拥有多名大学本科以上的工程师,更有一批经验丰富、技能娴熟的施工者!

Hardened wear-resistant flooring

Epoxy floor paint coating

Sports stadium, PVC plastic

Parking Floor

Commercial floor

Parking lot floor

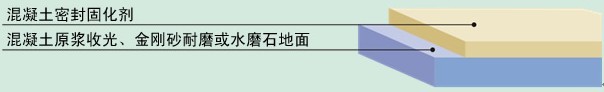

Concrete Seal Hardener

|

What is sealed concrete curing agent? |

|

|

|

The compounds penetrated into the concrete, through a series of complex chemical reactions, produces hard substances with the half-hydrated cement, free calcium, silicon oxide and other substances contained in the condensed concrete. These compounds ultimately make the concrete surface compactness improved and thus strength, hardness, wear resistance, and impermeability of concrete surface enhanced. |

|

How to work? |

|

Through complex chemical reactions, its final products would block and seal the structural pore of concrete, and as its strength improves, the surface hardness increases, and the compactness enhances along with impermeability. Reduce the water flow path to lower the intrusion of harmful substances, thereby greatly enhancing the concrete erosion resistance to chemicals. Therefore, the seal concrete curing agent can make the concrete surface sealed, strong, wear-resistant, and dust-free for a long time. |

|

|

|

Scope of Application |

|

◇ Used for indoor and outdoor emery wear floor, terrazzo floor, magma polished floor, super-flat floor, ordinary cement floor, and stone and other base surfaces, and suitable for factory workshops, warehouses, supermarkets, docks, airport runways, bridges, highways and other cement-based places. |

|

|

|

Features |

|

◇ Sealed and dust-free, hardened and wear-resistant; |

|

◇ Resistance to chemical attack; |

|

◇ Permanent gloss (the treated concrete floor presents the attractive luster as being waxed with the time growing); |

|

◇ Good aging resistance; |

|

◇ Easy for construction, and eco-friendly (colorless and odorless); |

|

◇ Reduced maintenance cost, and once construction for permanent protection. |

|

|

|

System Features |

|

◇ Sealed, rugged, wear-resistant, and dust-free in the long run; |

|

◇ More long-term commitment: Once treatment for all; |

|

◇ Gradual gloss at use; |

|

◇ General life span of 15-20 years; |

|

Technical Indicators |

|||

|

Test items |

Unit |

Technical Indicators |

Test results |

|

Flexural strength |

GB9966.1-2001 |

≥11.5 |

13.2 |

|

Flexural strength |

GB9966.1-2001 |

≥11.5 |

13.2 |

|

Wear ratio |

GB9966.1-2001 |

≥300 |

314 |

|

Mohs hardness |

GB9966.1-2001 |

≥5 |

8 |

|

|

|||

|

Construction Technology |

|||

|

Specific Practices and Requirements |

|||

|

1. Comprehensive polishing by use of a special 300-mesh epoxy resin polisher (after water processing) to let the clean and fresh concrete surfaces exposed. |

|||

|

2. Spray evenly Jieda seal concrete curing agent (0.4kg-0.5kg per square meter) onto the ground after polishing, keep the ground wet for 40 minutes to one hour, and when the surface become sticky, wash the whole surface with clean water, clear out all the water, and ensure natural dry for 24 hours or more. |

|||

|

3. After completely drying, comprehensively polish by use of the special 500-mesh epoxy resin polisher for initial polishing of the overall base level. |

|||

|

4. Comprehensively finish polish (2-3 times) by use of the special 1000-mesh epoxy resin polisher for full polish of the overall base level. |

|||

|

5. Clean the ground with the dedicated floor cleaning equipment. |

|||

|

|

|

||

|

|

Untreated concrete (4,000 times enlarged) |

Treated concrete (4,000 times enlarged) |

|

|

|

Water, oil and other dirt penetrate into the untreated concrete and stone structures through the natural pores. |

Effectively and permanently seal concrete or stone structures, namely, by chemical reactions, make concrete or stone structures become strong and compact objects |

|